The e-Commerce industry is a fertile ground for Data Science problems. The data science models are adapted by the internet commerce to achieve improved efficiency as well as better customer experience. In this blog, we discuss a number of optimisation problems that provide such advantages in the B2C (Business-to-customer) e-commerce industry. We focus on those problems that are formulated formally as optimisation problems in B2C e-Commerce and are solved by conventional optimisation or through random search/meta heuristic methods.

Like every data science model, it is important that the domain knowledge is integrated during formulation and solving the problem. The domain experts in this case are the supply chain operations, product, engineering and business teams.

Related Problems and Outline of the Blog

The e-Commerce supply chain consists of a number of associated data science problems such as customer address classification, address non-deliverability prediction, multiple fraud scenarios–their detection and mitigation, return prediction, and RTO (return to origin) problem. As the focus of the current blog is the optimisation problems, we choose to place them out of the scope of current discussion.

In the following sections, we briefly provide an overview of supply chain in e-commerce and discuss optimisation problems in Supply Chain Inbound and Outbound. The intention of the blog is to provide an indicative problem landscape of supply chain in e-commerce. An exhaustive list of problems depends on the nature of the business and the way it is organised. Since a discussion of the solution of each such problem would need a detailed discussion, we restrict to discussing the problem landscape alone. However, wherever relevant, we direct the reader to the published solutions in that area.

Supply Chain in e-Commerce

A catalog of an e-Commerce company contains items relevant to its business. It contains a list of items that the company deals with. For example, the catalogs of e-Bay, Amazon, Flipkart, Myntra, Nykaa, Tata 1mg and BigBasket are different from each other as their focus areas are not exactly the same although in some cases, there are large overlaps. Thus, the components of the supply chain such as inventory models, replenishment models, storage requirements, expiry criticality, quality evaluation and repeat purchase patterns too depend on the nature of the e-commerce industry.

Supply chain management systems help organisations make decisions on the following.

Supply chain management systems help organisations make decisions on the following.

- When and what to procure, transport and where to store,

- Optimal pick and pack at warehouse,

- Optimal automated inbound quality evaluation models,

- Optimal promise time,

- Achieve shorter delivery times,

- Faster return cycles,

- Provide external and internal tracking of status of the orders,

- Monitor inventory availability and stockout,

- Optimise inventory, inter city transportation and warehousing costs,

- Optimisation at delivery hubs and

- Plan procurement/production vis-a-vis dynamic customer demand.

Inventory Approaches

The e-commerce companies have the options [1] of the traditional method where they have stored inventory, drop-ship method where the retailer directly delivers items to customers and a hybrid method where both options are exercised. Each of these approaches have their relative advantages and disadvantages.

A nationwide e-commerce organisation with a hybrid approach, which combines traditional and drop-ship, would have to consider local demand of items in planning storage in the warehouse across the country.

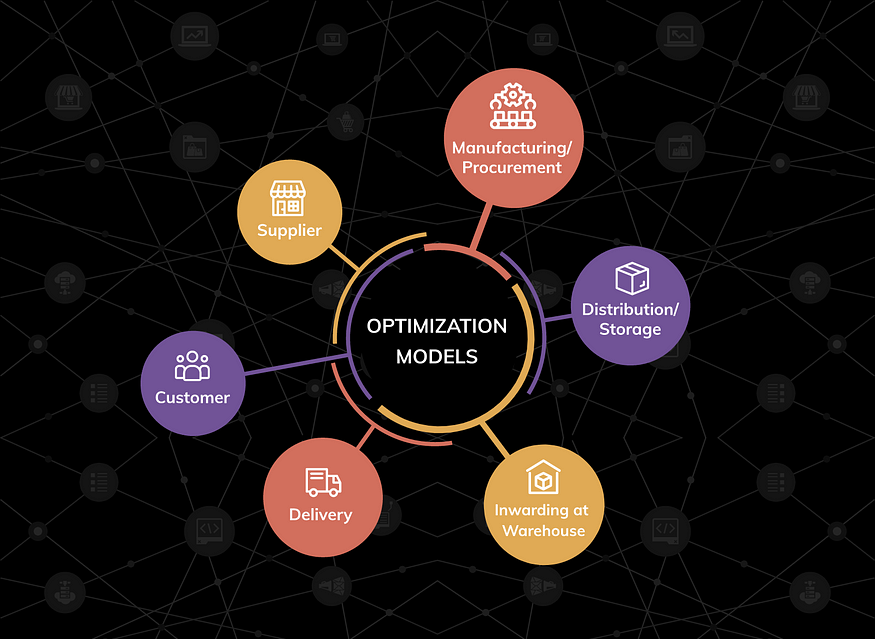

As a next step, we discuss optimisation models in the inbound supply chain.

Optimisation Models in Supply Chain Inbound

The inbound refers to the items that are received by the company and are placed for their sale. They consist of procurement, optimal stocking to prevent stockout, just in time (JIT) purchase, assortment plans, and optimal allocation to warehouses, etc.

Optimal assortment

It refers to identifying the best combination of items based on historical sales patterns, local, regional, national and international trends, demand prediction and most importantly, business directions as well as domain knowledge of the operations teams. Since it is critical to minimise the dead inventory, it is important to proactively arrive at optimal buying plans.

Inventory management

The cost of unsold inventory causes avoidable expenditure to the company. At the same time, stockout would result in bad customer experience and could result in loss of customer trust. Optimal Inventory Levels [2] is an important problem where a trade-off between unsold inventory and stockout is achieved.

Optimal Warehouse Allocation of the Planned Inventory

Optimal allocation of Inbound items to warehouses with constraint on delivery time in a predefined number of days [3] is an important model. Such a model needs to take regional demand into account. A systematic approach to this problem would help achieve faster delivery times and optimal usage of available inventory across the warehouses. Faster delivery is a critical component of customer satisfaction.

Optimal Item Pickup at the warehouse

Once the customer places the order, within the warehouse, the problem relates to arriving at an optimal number of pickers, and shipment assignment to pickers thereby minimising pickup time. This is done by taking into account historical picker performance, location of items in the bays, and faster turnaround times.

Optimal inventory placement inside a warehouse

Placement of inventory at the warehouse is essential so that the pickup time is minimised. It is achieved based on historical purchase patterns, products that are frequently purchased, products that are bought together, distance between staging areas as well as picker bay to various items.

Optimisation Models in Supply Chain Outbound

The outbound supply chain refers to promise time prediction[5], packing, address labelling, geographical grouping, transporting from mother hub to various warehouses, warehouse to delivery hub, shipment assignment and actual delivery to the customer.

Optimal packaging

The packaging sizes need to be optimised [4] for different products. The choice of exhaustive package sizes and recommendations of right packages for different products based on their volumes is an important optimisation problem that impacts the supply chain cost of a company.

Optimal Storage Prediction for Local Deployment Centers

In order to minimise the delivery time, it is necessary to store the expected set of items that could be ordered in local deployment centres some predefined number of days in advance. The related optimisation problem [6] considers historical orders during normal business days (BAU-Business As Usual) as well as Sale Days. Accordingly, those items are transported in advance and stored at the local deployment centres. The local deployment centres usually contain paid spaces which usually have a limited storage space. Additionally, there is the transportation cost that needs to be minimised. Thus, it is necessary to optimise the items that could be transported and stored.

Optimal DC Management

The delivery centres coordinate final last mile delivery. We discuss multiple optimisation problems in this area and elaborate some of them.

It is necessary to organize delivery centres in an optimised manner in terms of

- Number of delivery subareas,

- Creation and periodic reorganising of delivery hubs,

- Combining forward and reverse pickup,

- Minimise delivery agents,

- Plan for a combination of group deliveries through hyperlocal manner, and

- Make an optimal route planning.

Optimal shipment allocation to Delivery Agents at a Deliver Hub

In the usual practice, the delivery agents are assigned shipments by the manager of the delivery hub depending on the agents’ conventional routes or in an arbitrary manner. The latter leads to bias which needs to be minimised. It is important to assign shipments by taking the agents’ historical performance into account such as number of undelivered shipments, feedback from the customers on deliveries, timely delivery, package condition, etc. In addition to improved efficiency, it minimises human bias or manager’s personal preference in an assignment.

Optimal delivery plans

The route optimisation takes into account the number of shipments per route, actual recommended route for the agent, optimal grouping of shipments en-route the delivery, etc. Such optimisation problems focus on minimising the distance traveled, time taken for delivery, etc.

Summary

In this blog, we provided an overview of optimisation problems in the e-commerce supply chain. It is an attempt to provide the landscape. The list is indicative. The actual list of optimisation models depend on the nature of the e-commerce industry and priorities of the business teams. These problems are part of a larger set of data science problems in e-Commerce.

Further Reading

[1] Snyder, R. (2013). E-commerce and Supply Chain Management. ASBBS Proceedings, 20(1), 237.

[2] Li, J., Guan, M., & Chen, Z. (2020). Optimal inventory policy for fast-moving consumer goods under e-commerce environment. Journal of Industrial & Management Optimization, 16(4), 1769.

[3] Girish Sathyanarayana, Arun Patro(2020) Intelligent Warehouse Allocator for Optimal Regional Utilization https://arxiv.org/abs/2007.05081

[4] Yueyi, L., Xiaodong, Z., & Pei, W. (2019, December). A Cost-Minimization Model to Optimal Packaging Size in E-commerce Context. In Proceedings of the 2019 Annual Meeting on Management Engineering (pp. 35–41).

[5] Preethi V, Nachiappan Sundaram, Ravindra Babu Tallamraju. Online Fashion Commerce: Modelling Customer Promise Date. Data Science for Retail and E-commerce workshop (collocated with SIAM SDM ’21) https://arxiv.org/abs/2105.00315